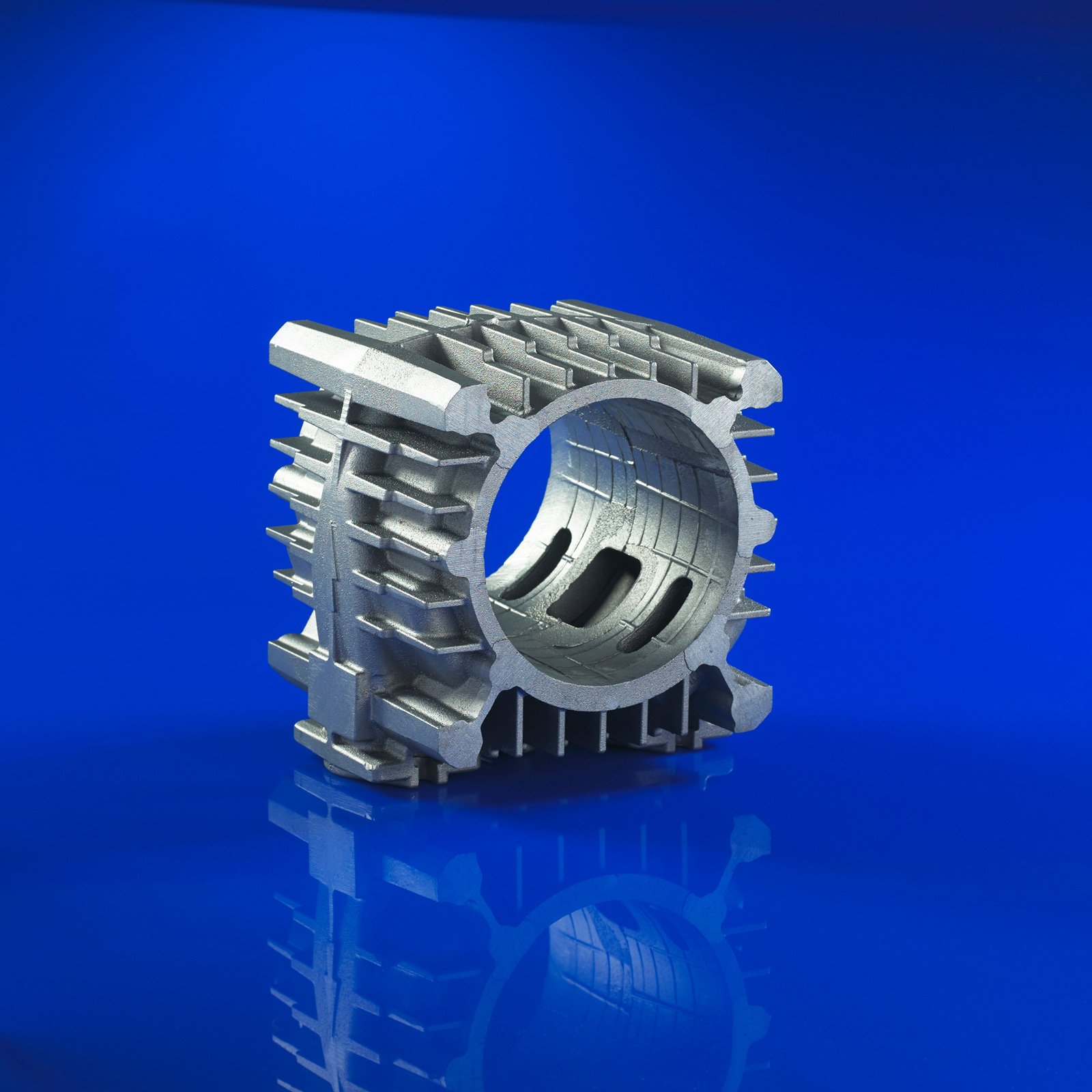

Specialists in the production of zinc & aluminium sand castings & gravity die castings

Our established zinc & aluminium foundry in the West Midlands produces high quality castings in various grades, sizes and quantities using the airset and gravity die casting processes.

5,000m² Facility

50+ Materials

5 Cold Box Core Blowing Machines

3 Dressing Robots

Would you like to discuss a project?

Telephone: +44 (0) 121 557 9831

Email: sales@newbyfoundries.co.uk

High or Low Volume Runs

From tens to tens of thousands, we have the flexibility to cater for both.

Wide Range of Sizes

Our variety of furnaces allow us to cast intricate parts from 100g up to large 150kg castings.

Zinc Gravity Die Casting

We are one of the few foundries who cast zinc alloys using the gravity die process.

Processes

Newby Foundries Light Alloys primarily produce castings using the airset moulding and gravity die casting processes. Gravity die casting is most suited to higher volume runs whereas airset moulding is most suited to low to medium volume production and large zinc or aluminium castings. Utilising the facilities of the Newby Foundries Group we are also able to offer 3D sand printed moulds & cores for prototypes or complex geometries. Therefore, we can provide customers with the most suitable casting solution for many applications, from 1 offs to thousands.

Find out more about the processes we offer below.

Airset Moulding

Cost effective resin tooling

Low to medium volume

Up to 150kg

CT9 tolerance

Cold Box Core blowing

Cost effective resin tooling

Low to high volume

CT9 tolerance

Gravity Die

Medium to high volume

Up to 20kg

Cost effective piece price

CT7 tolerance

3D Sand Printing

Furan system

1,800 x 1,000 x 700mm bed size

Layer thickness: 280 - 500μm

No tooling required

Undercuts possible

CT9 tolerance

Materials

We produce many grades of zinc and aluminium including those requiring solution & precipitation heat treatments. Customer specific grades are also available on request. Our range of furnaces allow us to cast zinc parts up to 80kg and aluminium parts up to 150kg.

We can produce the following materials. Non-standard and customer specific grades are available on request.

Aluminium

Al 99.5

Al-Si5Cu3

Al-Si12

Al-Si12Fe

Al-Si10Mg

Al-Si12Cu

Al-Si12CuFe

Al-Si5Cu1Mg

Al-Si12Cu

Al-Si12CuFe

Al-Si7Mg

Al-Si7Cu2Mn0.5

Al-Si17Cu4Mg

AlSi7Mg0.3

AlSi7Mg0.6

AlSi9Cu1Mg

AlSi5Cu3

AlSi7Mg0.3

Zinc

ZnAL4Cu1

ZnAl11Cu1

ZnAl27Cu2

Newby Foundries are committed to sourcing materials from companies that share our values in relation to human rights, ethics and environmental responsibility. We demand our suppliers comply with our code of conduct, and meet our sustainability expectations, including conflict free sourcing of materials. To ensure this commitment is fulfilled Newby Foundries ensures that its products are produced using only materials which can be proven to have originated from non-conflict sources.

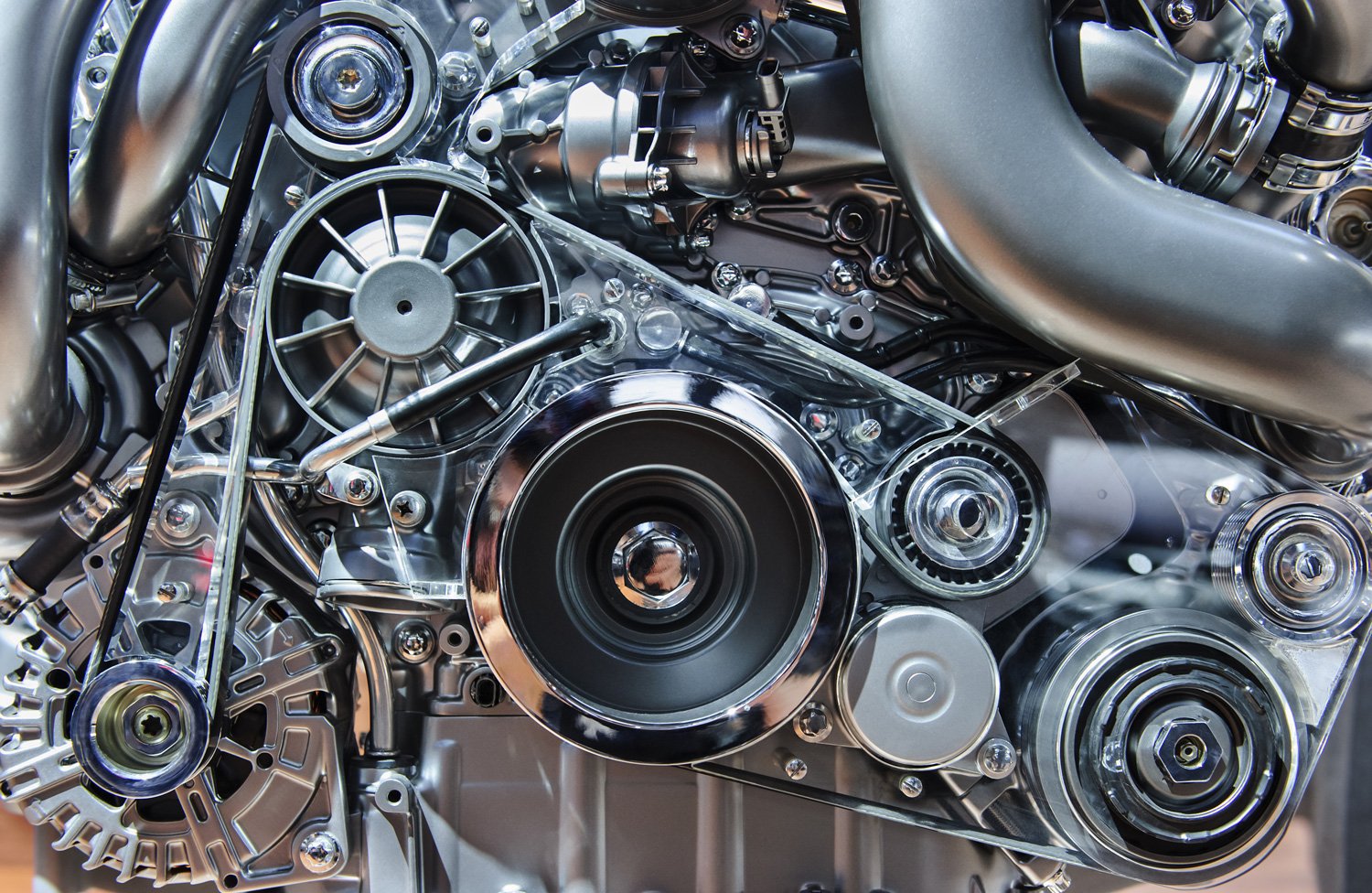

Sectors

Newby foundries light alloys operate in the following industries:

We supply castings such as pumps, fans, brackets, and housings to a diverse range of customers. These include automotive, electric vehicle, oil & gas, power generation and pump OEMs as well as general engineering.

Equipment

Core Making

4X 20L cold box core blowing machines

1x 10L cold box core blowing machine

Melting

22x electric holding furnaces

3x bulk melt furnaces

2x plc controlled rotary degassing units

1x rotary degassing unit

2x density index verification machines

4x plc controlled gravity die tilt rigs

Moulding

3x 5 tonne per hour airset mixers

Sand Reclamation

3x attrition units

Blasting

2x rotary hanging shotblast units

1x directional shotblast cabinet

Fettling

3x CNC dressing robots

Heat Treatment

2x heat treatment ovens

1x quench tank

Quality

Spectrograph

Brinell hardness machine

Pressure test unit

Other Services

Discover the services Newby Foundries Light Alloys can also assist with:

QUALITY

Material testing laboratory

Dimensional analysis reports

PPAP & APQP

MPI, DPI & X-ray

Pressure testing

Ultrasonic testing

FINISHING

Heat treatment

Impregnation

Plating

Painting

Passivating

Anachrome

Anodising

Divisions

Explore the Newby Foundries Group

The Newby Foundries Group produce high quality castings in a variety of materials, sizes & finishes across our 4 sites. Our range of casting processes, combined with our ability to develop castings from prototype through to production means we can provide customers with an optimal casting solution for many applications.

Our flexibility of processes, materials, quantities & sizes means we can find the optimum casting solution for many applications

Would you like to discuss a project?